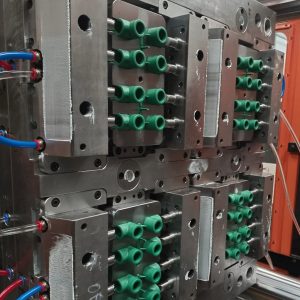

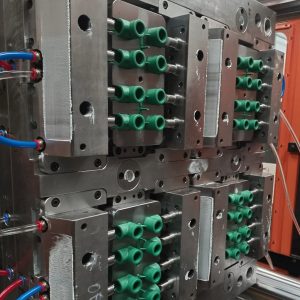

Molds

About our molds

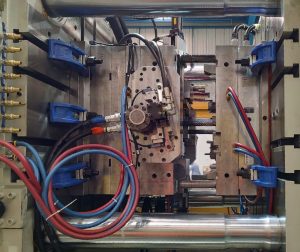

- Injection: Cold, hybrid and hot casting. Screw-off system, mechanical and hydraulic skids.

Products: Ideal for producing plastic parts with complex shapes, such as electronic components, product housings, toys, automobiles, etc. - Materials: Different types of plastics can be used, including thermoplastic plastics such as polypropylene, polyethylene, ABS, and others.

- Precision: The process offers high precision and repeatability in the production of parts.

Maintenance: Injection molds can be complex and expensive, but they allow for efficient series production. - Blow molding: Extrusion, blow and injection, thermoformed blow molding.

Products: Mainly used to produce containers such as bottles, jars, drums, and other hollow plastic products. Blow molding is also suitable for the manufacture of large parts with internal cavities. - Materials: The process generally uses thermoplastic plastics such as PET (polyethylene terephthalate), polyethylene (PE), and polypropylene (PP).

- Cost and time: Blow molds are generally simpler and faster to manufacture than injection molds, and products are also produced more quickly.

- Part design: Blow molded parts generally have a hollow structure and can be lighter than injection molded parts.

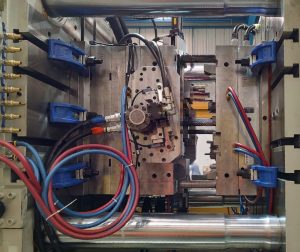

Electro erosion

Electrical discharge machining is a machining process that uses controlled electrical discharges to remove material from a workpiece. This process is primarily used to work hard metals or materials that are difficult to machine using conventional methods, such as milling or turning.

- The process is carried out in a bath of dielectric liquid (such as oil or water), which insulates the electrode and workpiece parts while facilitating the removal of material fragments.

- A series of electrical discharges occur between the electrode and the workpiece. Each discharge generates a small spark that melts and evaporates the workpiece material at that point.

- The discharges are high intensity, but short duration, allowing precise control of material removal.

Hot Casting Systems

Unlike cold runner systems, these systems have a direct impact on reducing or eliminating resin waste. By also reducing overall cycle times, energy consumption is lower and there is a higher volume of parts produced per molding cycle even when using multi-cavity molds.

If you have any technical questions, please write to us.

For more information about our products and services, please send us your information so we can contact you as soon as possible to answer your questions.

Contact

Telephone

01 (722) 2169364.

ventas@polisol.com.mx